close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

PEC2005A

COSO

Product Description

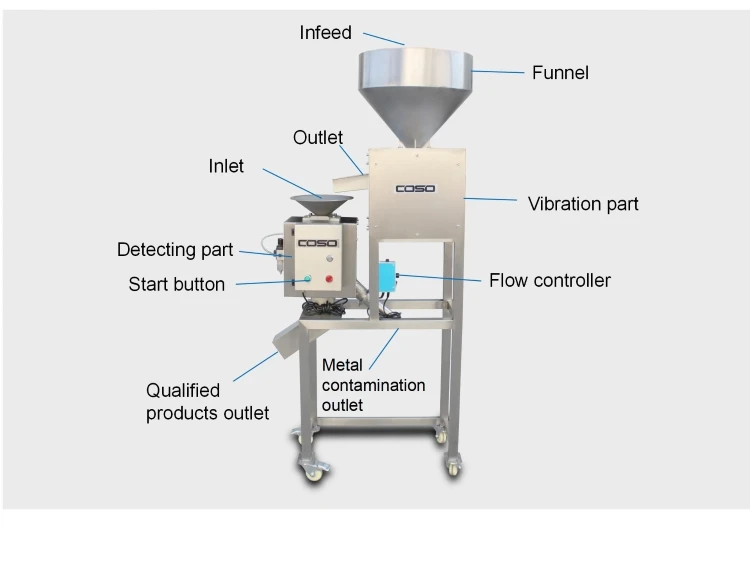

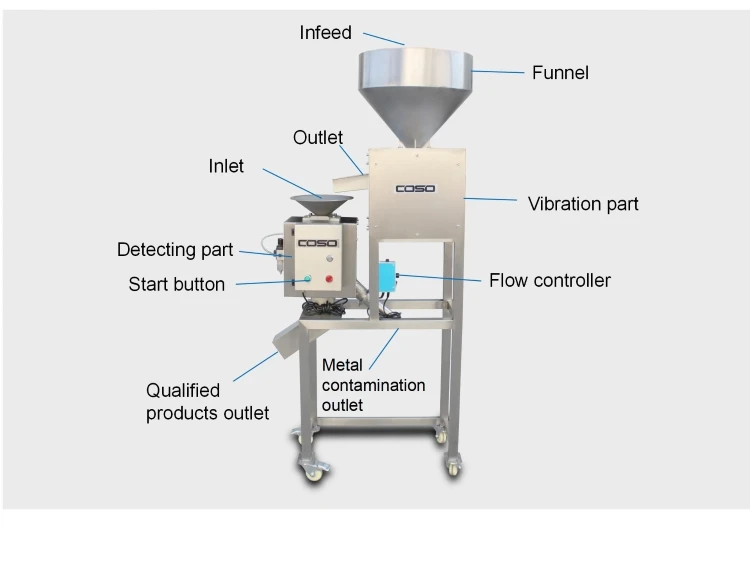

Vibration feeder metal separator is designed to remove metal contamination from products. When products contain a lot of metal pollution or the pipe diameter is too small, a vibrating feeder can control material flow, effectively solve the problem of clogging and improve detection performance.

This machine is widely used in plastic, pharmaceutical, food, chemical and other industries. It's able to quickly detect and automatically separate iron, copper, aluminum, stainless steel and other metal impurities from materials.

It's suitable for granular, flake material and products with poor fluidity.

Application(included but not limited to)

Product Detail

Product Feature

1.The flow speed and detecting amount are controllable, effectively preventing the metal separator from clogging.

2.The operation is very simple.

3.A variety of aperture diameter can be chosen, which can meet all practical applications.

Product Parameter

Model | Inner Diameter (Фmm) | Sensitivity | Air Compression | Max Throughput(L/h) | Material temperature | Defectives eliminated time | |

FeΦ | SUSΦ | ||||||

PEC2005A-30 | 20 | 0.3mm | 0.8mm | 3~5Bar | 300 | < 80℃ | 0.3~5s |

PEC2005A-50 | 40 | 0.5mm | 1.0mm | 3~5Bar | 2000 | < 80℃ | 0.3~5s |

PEC2005A-70 | 60 | 0.8mm | 1.2mm | 3~5Bar | 5000 | < 80℃ | 0.3~5s |

PEC2005A-100 | 80 | 1.0mm | 1.5mm | 3~5Bar | 12000 | < 80℃ | 0.3~5s |

PEC2005A-120 | 100 | 1.2mm | 2.0mm | 3~5Bar | 16000 | < 80℃ | 0.3~5s |

PEC2005A-150 | 130 | 2.0mm | 3.0mm | 3~5Bar | 25000 | < 80℃ | 0.3~5s |

PEC2005A-170 | 150 | 2.5mm | 3.5mm | 3~5Bar | 44000 | < 80℃ | 0.3~5s |

Notes:

1.All the sensitivity parameters above is on the basis of the test block falling freely through the pipe, the actual sensitivity will be affected by the product's characteristics and working environment.

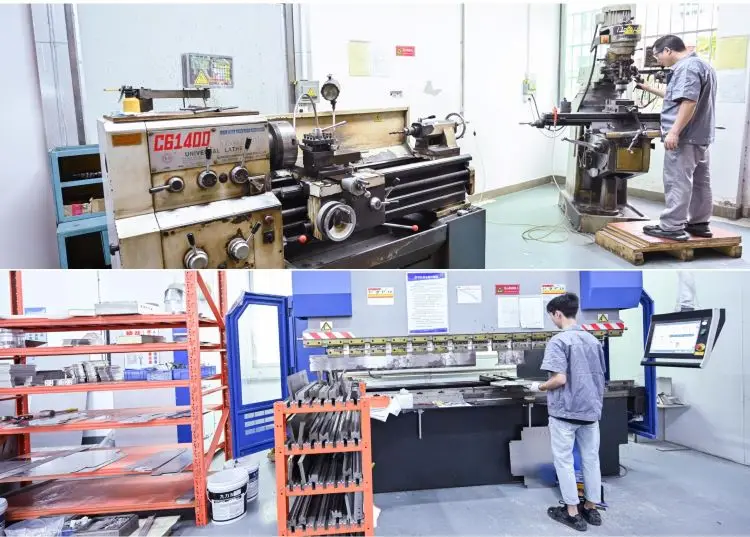

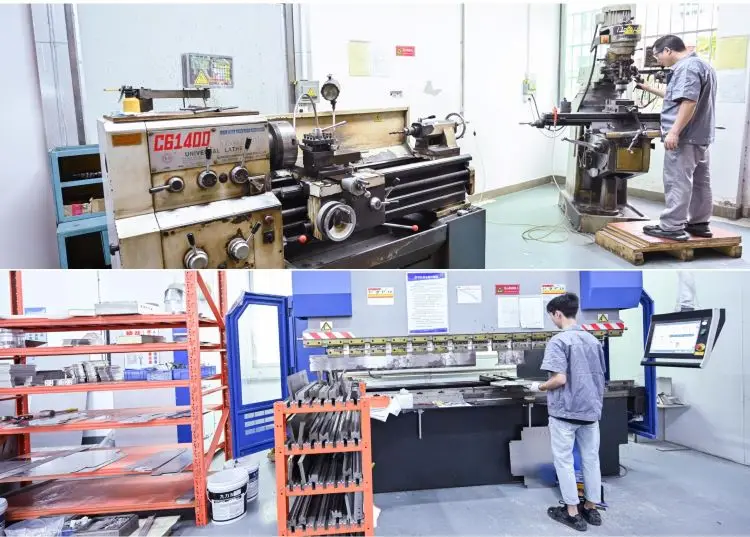

Company Scene

Certification

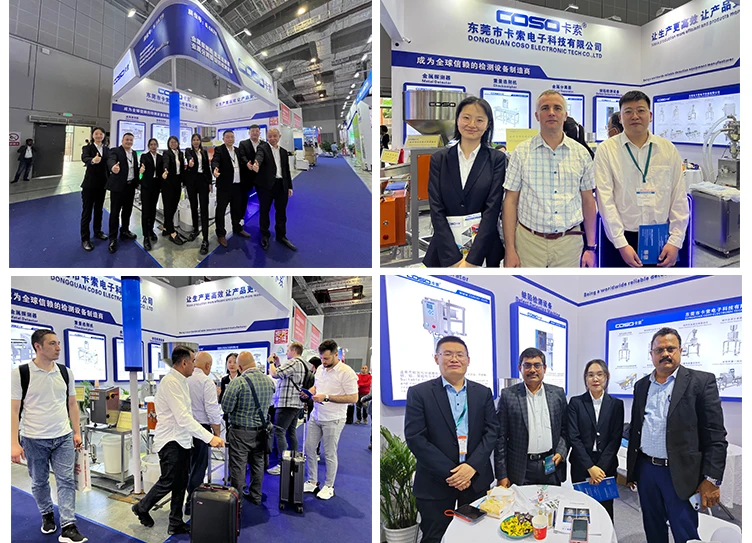

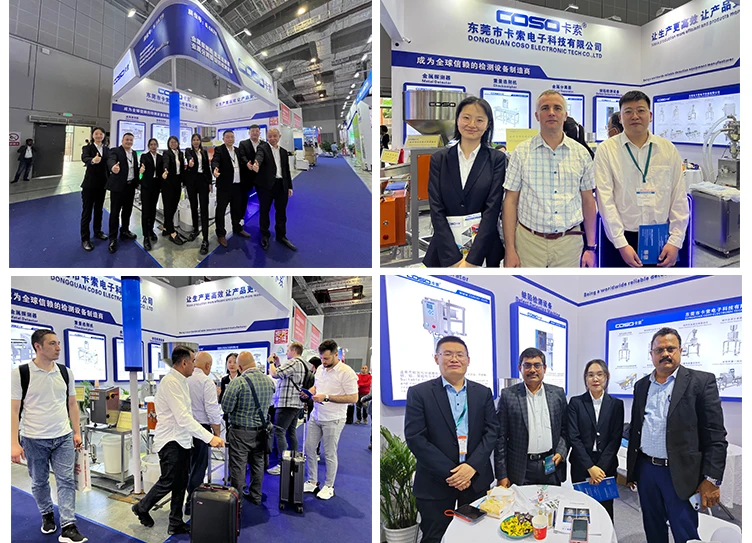

Exhibition

Packing and Delivery

FAQ

1. Q: What’s your mininum order quantity?

A: One set.

2. Q: Do you accept customization?

A: Yes, and it’s one of our advantages.

3. Q: How long is your delivery time?

A:Once we reach an agreement and the payment is received, the production process starts immediately, basically the lead time is 15 days.

4. Q: How about the packing for machine? Would it be easily damaged during transportation?

A: We use standard export wooden case for package which is strong enough for transportation.

5. Q: How about your after-sale service?

A: First, if you don’t know how to install or use the machine, our staff will provide detailed description and video to help you, we can also get online to have instant communication.

Second, if you have continual purchase needs, you can send people to our company and we can provide operation training.

Third, all of our products have one year warranty. If the core accessories went wrong and can’t be fixed, you can exchange for a new one.

Last, if the problem is extremely serious, we can send engineers to your company to help.

Product Description

Vibration feeder metal separator is designed to remove metal contamination from products. When products contain a lot of metal pollution or the pipe diameter is too small, a vibrating feeder can control material flow, effectively solve the problem of clogging and improve detection performance.

This machine is widely used in plastic, pharmaceutical, food, chemical and other industries. It's able to quickly detect and automatically separate iron, copper, aluminum, stainless steel and other metal impurities from materials.

It's suitable for granular, flake material and products with poor fluidity.

Application(included but not limited to)

Product Detail

Product Feature

1.The flow speed and detecting amount are controllable, effectively preventing the metal separator from clogging.

2.The operation is very simple.

3.A variety of aperture diameter can be chosen, which can meet all practical applications.

Product Parameter

Model | Inner Diameter (Фmm) | Sensitivity | Air Compression | Max Throughput(L/h) | Material temperature | Defectives eliminated time | |

FeΦ | SUSΦ | ||||||

PEC2005A-30 | 20 | 0.3mm | 0.8mm | 3~5Bar | 300 | < 80℃ | 0.3~5s |

PEC2005A-50 | 40 | 0.5mm | 1.0mm | 3~5Bar | 2000 | < 80℃ | 0.3~5s |

PEC2005A-70 | 60 | 0.8mm | 1.2mm | 3~5Bar | 5000 | < 80℃ | 0.3~5s |

PEC2005A-100 | 80 | 1.0mm | 1.5mm | 3~5Bar | 12000 | < 80℃ | 0.3~5s |

PEC2005A-120 | 100 | 1.2mm | 2.0mm | 3~5Bar | 16000 | < 80℃ | 0.3~5s |

PEC2005A-150 | 130 | 2.0mm | 3.0mm | 3~5Bar | 25000 | < 80℃ | 0.3~5s |

PEC2005A-170 | 150 | 2.5mm | 3.5mm | 3~5Bar | 44000 | < 80℃ | 0.3~5s |

Notes:

1.All the sensitivity parameters above is on the basis of the test block falling freely through the pipe, the actual sensitivity will be affected by the product's characteristics and working environment.

Company Scene

Certification

Exhibition

Packing and Delivery

FAQ

1. Q: What’s your mininum order quantity?

A: One set.

2. Q: Do you accept customization?

A: Yes, and it’s one of our advantages.

3. Q: How long is your delivery time?

A:Once we reach an agreement and the payment is received, the production process starts immediately, basically the lead time is 15 days.

4. Q: How about the packing for machine? Would it be easily damaged during transportation?

A: We use standard export wooden case for package which is strong enough for transportation.

5. Q: How about your after-sale service?

A: First, if you don’t know how to install or use the machine, our staff will provide detailed description and video to help you, we can also get online to have instant communication.

Second, if you have continual purchase needs, you can send people to our company and we can provide operation training.

Third, all of our products have one year warranty. If the core accessories went wrong and can’t be fixed, you can exchange for a new one.

Last, if the problem is extremely serious, we can send engineers to your company to help.